- Home

- Products

- Road guardrail

- Traffic guardrail

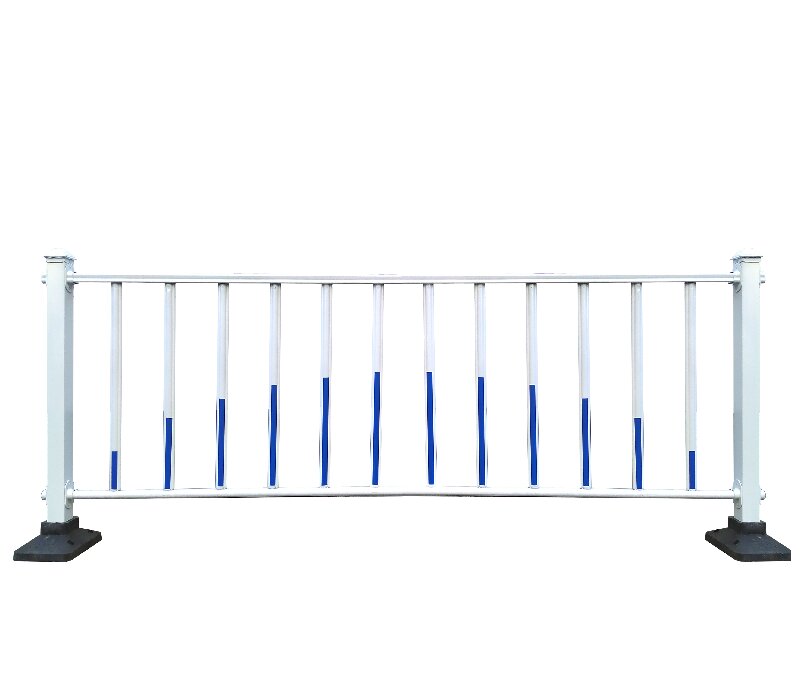

Traffic guardrail

-

Stable structure and excellent anti-collision performance

The core adopts a "horizontal bar+vertical bar" reinforcement, integral welding or modular splicing design. Some high-risk scenarios (such as highways and expressways) use reinforced structures such as corrugated beams and anti-collision columns, which can withstand the impact force of vehicles of different tonnages (in accordance with the GB/T 26941 series traffic guardrail standards), and are not easily scattered or deformed after impact, effectively buffering the impact force and reducing the degree of accident injuries. -

Corrosion resistant and durable, suitable for complex environments

The substrate is mainly made of Q235 low-carbon steel and galvanized steel, and high-end models use aluminum alloy or stainless steel. The surface is treated with dual anti-corrosion treatments such as hot-dip galvanizing, electrostatic spraying, and hot-dip molding, which can resist the erosion of rainwater, ice and snow, ultraviolet rays, and acidic and alkaline substances (such as coastal salt spray and road snow melting agents). The normal service life can reach 6-12 years in harsh outdoor environments, with low maintenance frequency and low cost.

Clear warning and strong guidance: The color scheme is mainly high visibility tones (such as white, yellow, blue), and some styles are equipped with reflective film, reflective strips, or night light coatings. During the day, the road boundary is defined by vivid colors, and at night, the light of the headlights is reflected to improve the recognition of the guardrail, helping drivers quickly judge the lane range, especially suitable for complex scenes such as intersections, ramps, tunnel entrances and exits. -

Efficient installation and wide adaptability

Using standardized modular production, the conventional length of a single section is 2-4m, which can be quickly spliced and extended to meet different road length requirements; The fixed method is flexible, supporting pre embedded (permanent installation, such as main roads and bridges), expansion bolt fixation (hardened road surface, such as secondary roads), and mobile base (temporary control, such as construction sections and activity diversion), which can meet the installation conditions of various traffic scenarios. -

Economical and practical, with high cost-effectiveness

The material selection takes into account both strength and cost. Low carbon steel is suitable for large-scale municipal projects, while aluminum alloy is lightweight, easy to install, and has high recycling value; Post maintenance is simple, only requiring regular cleaning of surface stains. Local damage can be replaced with individual modules without the need for complete disassembly, reducing maintenance costs. -

Urban road scenarios:

separation of motor vehicle lanes and non motor vehicle lanes on urban main roads, secondary roads, and branch roads, median barriers on roads, and protection of pedestrian boundaries; The diversion and isolation of intersections, roundabouts, and bus lanes regulate traffic flow and avoid mixed traffic and illegal crossings. -

Highway/Expressway Scene:

Central median strip of highway, boundary of emergency lane, and isolation of entrance and exit ramps; Expressway crash barriers are designed to resist high-speed collisions from vehicles, prevent them from rushing out of the road or entering the opposite lane, and ensure the safety of high-speed traffic. -

Bridge and Tunnel Scenarios:

Protective guardrails on both sides of the bridge, transition guardrails at tunnel entrances and exits, adapted to the high-altitude environment of the bridge and the characteristics of insufficient tunnel lighting, strengthen protection and warning effects; The guardrails for cross sea/cross river bridges should be made of salt spray resistant materials to enhance durability. -

Special traffic scenario:

Temporary isolation barriers (mobile) on construction roads to guide vehicles to detour; Road guardrails (raised and reflective strips) around schools, hospitals, and commercial districts to ensure safety in densely populated pedestrian areas; Scenic area roads and township road guardrails (economic type), suitable for the protection needs of low traffic scenarios. -

Other supporting scenarios:

isolation of parking lot entrances and exits, lane separation at toll stations, internal road protection within the park, etc., extending the practical scope of traffic barriers.

Core material: The main structure is made of Q235 low carbon steel and hot-dip galvanized steel (conventional version); Aluminum alloy, 304 stainless steel (high-end version); Q235 strip steel for waveform beam guardrail

Size specifications:

Height: sidewalk guardrail 60-100cm; motor vehicle lane isolation guardrail 80-120cm; highway/bridge guardrail 120-150cm

Single segment width: 200cm, 300cm, 400cm (customizable)

Structural details:

Vertical pole: diameter 14-20mm round steel or 20 × 20mm, 25 × 25mm square steel, spacing 10-15cm

Horizontal bar: 1-2 pieces each, with specifications of 40 × 40mm, 50 × 50mm square steel or 32mm, 42mm round steel; The width of the waveform beam guardrail plate is 310mm, 432mm, and the thickness is 2.5-4.0mm

Column: circular column with diameters of 48mm and 60mm; Square columns with dimensions of 50 × 50mm and 60 × 60mm; corrugated beam guardrail columns with diameters of 114mm and 140mm

Surface treatment: hot-dip galvanizing+electrostatic spraying (mainstream), hot-dip molding, fluorocarbon spraying (corrosion resistant upgraded version)

Color: White (RAL9010), Yellow (RAL1023), Blue (RAL5010), Dark Grey (RAL7016), supports customized traffic specific colors

Latest News

Latest news about guardrails.

Our Services

Our Services

Contact Us

Get personalized guardrails advice for system choice & savings.